Haul ropes and carrying-hauling ropes are classed as non-redundant ropeway components, and their reliability is crucial for the safety and availability of the installation. With TRUscan, Fatzer’s innovative non-contact MI testing device plus appurtenant software, it is now possible to use a combination of non-contact rope travel measurement and wire break detection to precisely predict the rope discard date, among other things. TRUscan can be used for non-contact testing for broken wires in haul ropes up to a diameter of 64 mm.

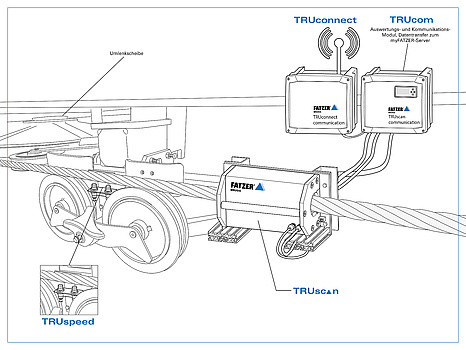

In addition to its top-quality ropes Fatzer, the Swiss ropeway rope manufacturer based in Romanshorn, also has an outstanding reputation for its customer-focused range of services such as splicing, maintenance, repair and servicing of high-performance ropes. In collaboration with Stuttgart University’s globally recognized Institute of Mechanical Handling and Logistics (IFT), Fatzer has now further expanded its range of services with the introduction of TRUscan, a non-contact rope testing device for mobile operation and especially permanent installation that detects wire breaks and rope travel distance fully automatically. The data measured can be read out remotely via Fatzer’s web-based customer portal, which makes on-site acceptance by MI experts or test institutes a thing of the past except where an accredited test result is required. The TRUscan rope tester is a magnetic induction testing device, in which a test coil measures the magnetic stray field of the rope, thus providing an insight into the inner workings of the moving rope. Wire breaks are detected with millimeter precision and are automatically displayed in a defects list.

The effectiveness of the system was demonstrated in a long-term test performed on Fatzer’s own rope testing cableway involving opening the test rope and comparing the measured results with the wire breaks revealed through visual inspection. At the same time, resistance to the elements and the accuracy of the system under diverse climatic conditions, including very high humidity and very low temperatures, were also confirmed. The housing of the test equipment complies with the IP64 standard, meaning that it is suitable for use in extremely cold environments or salty and humid air, as in the case of ropeways by the sea, for example.

Testing can be triggered manually or remotely by the ropeway operator. The system can also be programmed for test runs at pre-defined intervals. The data captured – rope travel through the device in meters, and the number and position of any wire breaks – is stored in XML format on a central server either via the Internet or wirelessly using 3G. A special algorithm converts the data measured into a convenient diagram indicating wire break status and approximate rope discard, which is stored in a digital twin. This permits accurate predictions to be made of the need for refurbishment measures including splice renewal, thus minimizing ropeway system downtime.

![[Translate to English:] Foto: Leitner](/fileadmin/_processed_/a/8/csm_Vertragsunterzeichnung_Narvik_6_copyright_LEITNER_print_501f2d5c24.jpg)

![[Translate to English:] (c) Doppelmayr](/fileadmin/_processed_/b/3/csm_85-ATW_Stechelberg-Muerren_Lauterbrunnen_CHE_001_6442c0520d.jpg)