The opening of a chairlift from Heiligenblut to the Rossbach midline station on November 29, 1964 marked the beginning of ski area development at the foot of Austria’s highest mountain. The driving force behind the Großglockner Seilbahn Ges.m.b.H. was the local mayor Georg Lackner together with local entrepreneurs like Josef Schmidl, who later became the company’s managing director.

One of a kind

When a tunnel was built between Fleiss and Rossbach for the Fleiss hydroelectric power plant, it was suggested that it could later be used for a ropeway connecting the Rossbach chairlift midline station (now a gondola lift) with the Fleiss - Hochfleiss surface lifts (now a chairlift and a surface lift). The line would cross two avalanche paths and the narrow valley of the Großfleissbach stream. Many years later the idea was put into effect with the construction of the Fleissalm Tunnel Lift, which is still a unique piece of underground ropeway engineering today.

The ropeway manufacturers contacted at the time all argued that a ropeway could not be built in a tunnel that was so low and narrow. Only the former ropeway manufacturer Waagner-Biró, who already had some experience with track-based industrial suspension ropeways, was willing to draw up preliminary plans. The innovative solution presented was described as a “rope-hauled monorail suspension system with reversible operation and a midline passing point”. For the line of the track, the planners made use of the existing power plant tunnel with a 500 mm diameter pipe installed on one side. In summer, when the ropeway is not operating, the tunnel functions as an open spillway with a water depth of up to 0.5 m.

In order to avoid the avalanche paths, those sections of the line were routed underground in a new concrete tunnel that is curved on plan. This is followed by an avalanche-proof concrete bridge over the Großfleissbach leading to the beginning of the original hydropower tunnel. The bridge has a hollow trapezoidal cross section, and the line of the ropeway is accommodated inside it. In the lower section of the line, the ropeway branches off from the old power plant tunnel into another new concrete tunnel. Between the bottom station and the mouth of this tunnel, there is a 65 m long steel bridge on which the ropeway runs in the open air.

Challenge for the planners

Implementation of this innovative solution demanded great ingenuity on the part of the planners. The track for the four-wheel carriages consists of a steel section with a round steel bar welded to it. A total length of 1,650 meters of sectional steel weighing about 150 tons was used for the track. The carriages are capable of negotiating the tightest horizontal and vertical curves; the ropeway has a minimum horizontal radius of 100 m and a minimum vertical radius of 35 m. The fixed spring-loaded haul rope grips have specially designed jaws to ensure that the rope is always correctly located in the line sheaves including the inclined sheaves on the curved sections of the line.

Thanks to the rigid track structure, clearance above ground remains constant over the full length of the line. The steel track sections had to be installed with maximum precision in order to guarantee the high quality of the ride. To prevent lateral swing in the cars in the tunnels and stations, two horizontal plastic rollers mounted on the underside of the cars run in a rail in the form of U or angle sections installed in the guideway.

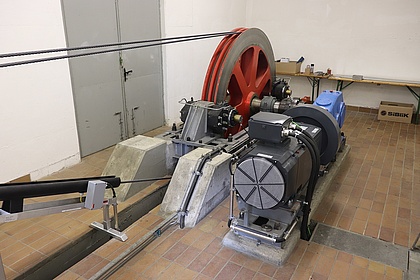

The drive with the twin-grooved bullwheel is located in the top station, while the haul rope tensioning system with the counterweights is located in the bottom station.

Each trainset consists of eleven cars for five passengers each. The cars are connected with a coupling specially designed to prevent contact between the individual cars during braking or acceleration. Despite the differences in gradient, the suspension ensures that the cars always remain in the horizontal position. Each cabin is equipped with interior lighting and an intercom. The doors are operated by a linear motor with limit switches integrated in the roof of the cars.

For the 2021/22 winter season, the complete electrical system was refurbished by the Frey Austria company. In addition, wi-fi and smoke detectors were installed in all the cars. Today the Fleissalm Tunnel Lift is still a key facility for the ski area: It is the only way to cross the gully of the Großfleissbach for the return trip from the Fleiss - Hochfleiss area to the Rossbach midline station.

![[Translate to English:] (c) Doppelmayr](/fileadmin/_processed_/b/3/csm_85-ATW_Stechelberg-Muerren_Lauterbrunnen_CHE_001_6442c0520d.jpg)