The fact that the DirectDrive is a 100% in-house solution – from the planning and development work to the engineering – is the key to top product quality and continuous innovation leadership. With the company’s long years of experience, Leitner can guarantee maximum product expertise plus advisory competence for the right solution for every requirement. “From the drawing board to the ski slope” – this distinctive quality advantage has attracted customers all over the world for more than twenty years now. As a wholly in-house product, the “Original by Leitner” is always state of the art, with the company’s research activities constantly benefitting the DirectDrive.

Leading through innovation in terms of efficiency and reliability

With the Leitner DirectDrive, the highest technological standards combine with maximum convenience in terms of operation and maintenance. The practical advantages are particularly clear with regard to ease of repair: Repairs can normally be completed within a few hours without curtailing the running of the system. With their very low weight, the coils, for example, can be replaced particularly quickly and easily. Nor do the station panels need to be opened to perform any work on the system, so that downtime is a thing of the past.

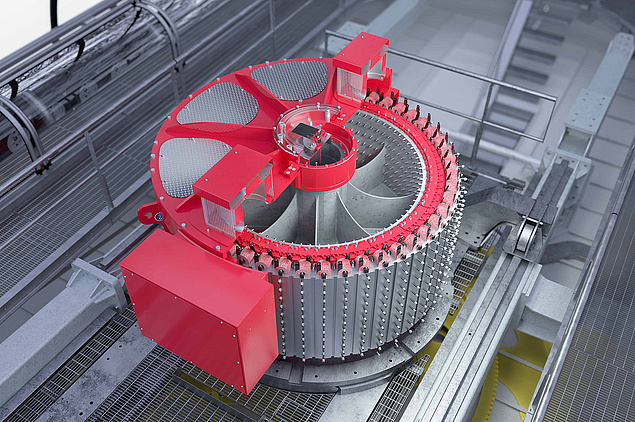

The DirectDrive also achieves top marks when it comes to efficiency and flexibility. Leitner’s perfected technology achieves up to 94% efficiency in the partial to peak load range. The redundant design of the DirectDrive also contributes to the outstanding level of performance. In particular, the use of multiple segments greatly increases operational reliability; with a correspondingly oversized motor, the required output can be supplied to the system even in the case of a segment malfunction.

The flexibility of the Leitner DirectDrive is clearly demonstrated by the underground funicular in Serfaus, which features the first DirectDrive with a vertical bullwheel, a useful alternative for aerial tramways, funiculars and bulk material conveyor belts. It helps make the Leitner DirectDrive the ideal solution for all types of ropeways.

![[Translate to English:] (c) Doppelmayr](/fileadmin/_processed_/b/3/csm_85-ATW_Stechelberg-Muerren_Lauterbrunnen_CHE_001_6442c0520d.jpg)