It all began in Saas Fee

Following the opening of the Metro Alpin underground ropeway from Felskinn to Mittelallalin in Saas Fee in 1984, visitor totals in the glacier ski area increased to such an extent that the 3.6 km long Saas Fee – Felskinn reversible built in 1969 as a feeder installation with a transport capacity of just over 500 pph was no longer equal to the task. As the valley terminal is several hundred meters from the center of the resort and skiers were confronted not only with long lines but also with a long walk in all their gear to the boarding point in the pedestrians-only resort, it made sense to find a new line for the replacement installation. The planning brief for the new installation was to provide additional capacity, relocate the bottom terminal to a central site in the resort and make it blend in as unobtrusively as possible with the local scenery. The new ropeway was to combine high capacity with good stability in side winds, and the line was to include a 1,300 m span across avalanche-prone slopes, with track ropes with enough vertical clearance to avoid tree felling. The upper station of the first stage was to be located next to the mid-station of the reversible at no. 4 tower (Morenia), which can be used to change onto the Egginer surface lifts. A second, shorter stage was to be built at a later date from Morenia to Felskinn. To meet these specifications with existing ropeway systems, it would have been necessary to build two parallel reversibles with full-size cabins or a DMC/Funitel, although the latter involved concerns with regard to haul rope behavior in a 1,300 m span.

Birth of a new ropeway system

The only convincing solution was to develop a new ropeway system. Luftseilbahnen Saas Fee, with Hubert Bumann as Director and Member of the Administrative Board, expressed their willingness to embark on this costly pioneering project.

In 1989 the answer to the ropeway engineering challenge was found by the Swiss company Von Roll Transportsysteme of Thun with the help of the design engineers Fritz Feuz and Gottfried Hofmann1) in the form of a ropeway that combined the advantages of a bicable reversible with those of a continuously circulating ropeway – the 3S gondola lift.

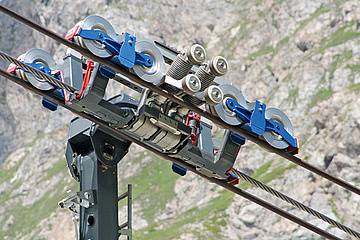

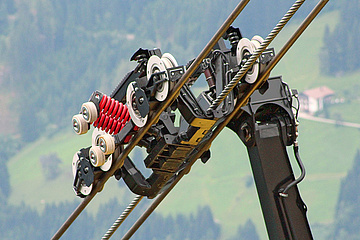

In principle, the system is a detachable bicable circulating ropeway with twin, permanently an-chored track ropes and a continuous haul rope. It offers a considerable advantage with regard to the length of the spans that can be handled with the haul rope running over slack carriers fitted between the track ropes. In addition to haul rope support, this rope configuration provides additional stabilization for the twin track ropes, which give the tricable gondola lift its extra stability in windy conditions. As a pleasant side effect, the use of slack carriers for rope guidage also reduces the amount of travel required in the haul rope tensioning system in comparison with a bicable circulating system. Above all, tricable systems can be built with rope spans of up to 3,500 m. (The longest rope span on a 3S gondola is currently the middle span of the Peak 2 Peak Gondola in Canada, which is 3,034 m long – see below). That is far more than a bicable circulating system, with only one track rope, can handle. In the case of a bicable circulating ropeway, the haul rope is only supported in the rope span by the grips on the carrier carriage. During loading or emptying of the system, the first or last grips on the cabins take the full haul rope load in the individual spans. That imposes a limit on maximum rope span of a few hundred meters.

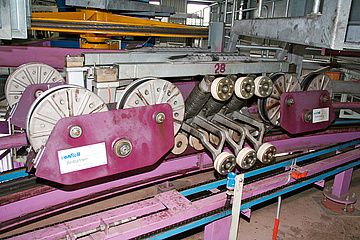

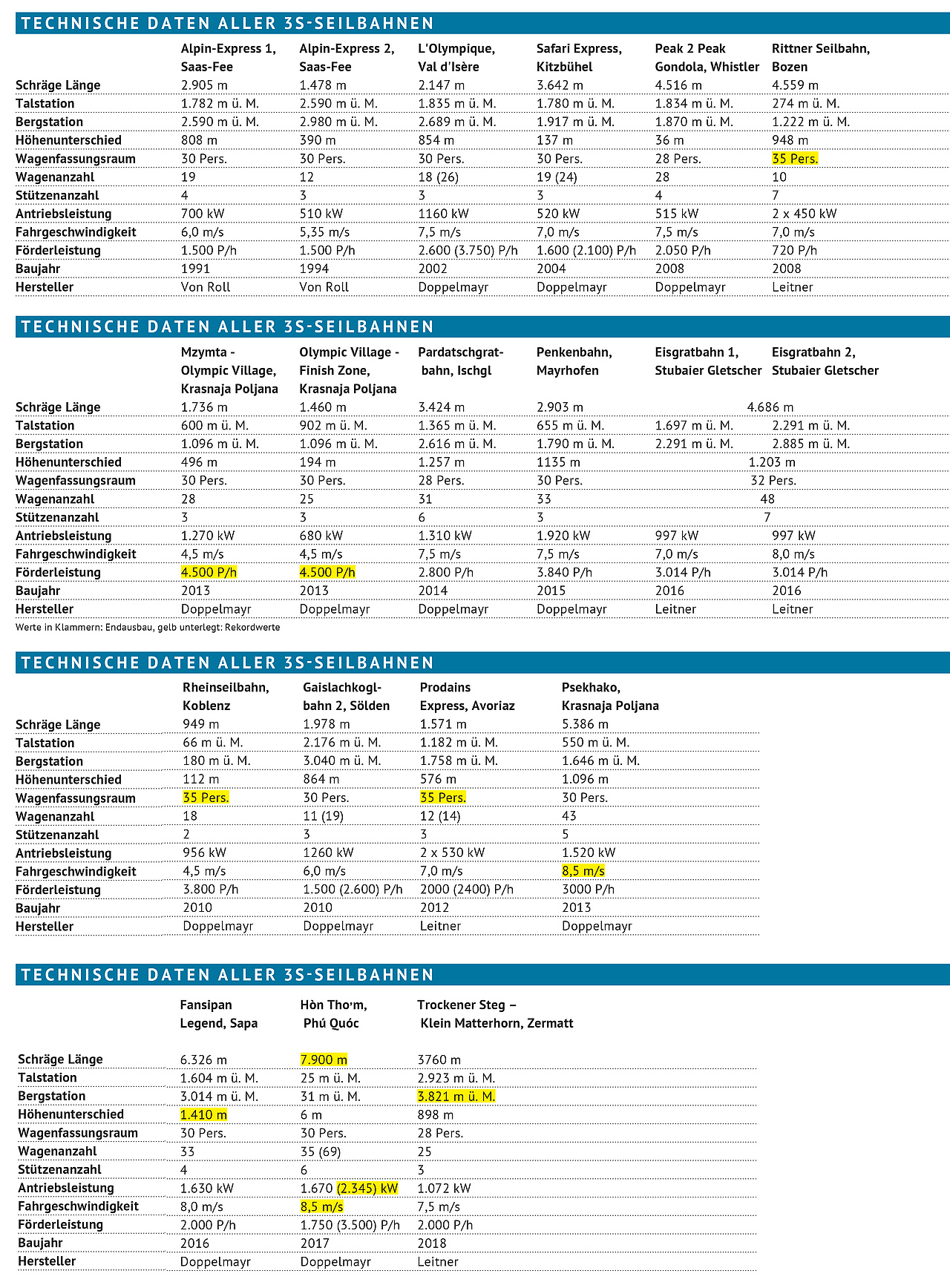

The detachable carriages on all tricable gondola lift installations have eight wheels, four per track rope. Tire banks are used to transport the carriers through the stations at walking pace. With cabins designed to carry between 28 and 35 persons, these systems can achieve a transport capacity of 6,000 pph. The current record of 4,500 pph is held by the two Krasnaya Polyana tricable installations in Sochi.

The Von Roll test installation

In order to test the behavior of the system and check all safety aspects prior to construction of the first 3S gondola lift in Saas Fee, Von Roll built a full scale test installation with a 23 m high tower and a line length of 300 m on the company's grounds in Thun and conducted trials for about two months. The company invited representatives of the Swiss Ministry of Transport to observe the trials and generally familiarize themselves with the tricable system. That was done to avoid the need for costly and time-consuming on-site tests and to be able to supply the customer with a ready-to-go, tried and tested installation. The tests were conducted with an original cabin traveling at speeds of up to 7.0 m/s on the line and included various operating situations on the station turnaround. Von Roll's tricable gondola lift carriages comprise two half-bogies with four wheels each and three haul rope grips in the middle.

First installations in Saas Fee

On September 10, 1991 the first cabin was launched on the line of the first stage of the Saas Fee installation aka Alpin Express. The 30-passenger cabins were designed and engineered by the Gangloff company. The new ropeway fully met the expectations placed in it and after 25 years of public service is still running in more or less its original condition as the main feeder installation for the ski area. The only fly in the ointment was the overrun on the construction costs, which finally came to CHF 41 million.

With a line that crosses an avalanche zone and wooded terrain, an evacuation ropeway had to be provided for passenger rescue from an immobilized cabin. As tricable ropeways, like bi-cable circulating systems, make it difficult for a rescue gondola to be designed to pass over the carriers, the Alpin Express 1 was built with an independent, winch-operated evacuation ropeway located above and in the axis of the two lines of the 3S lift. A two-person rescue cage is used to lift stranded passengers from the main cabin to the evacuation cabin, which also has a capacity of 35 persons.

Because of the high costs of the first tricable installation, the plans for a second stage were reassessed; cost saving options were sought and comparisons made with the Funitel system. Finally, a few economizing measures were found and the idea of a tricable gondola lift for the second stage from Morenia to Felskinn retained. The two stages operate independently, so that passengers have to change in the mid-station. After completion of the second stage in 1994, Von Roll did not build any more tricable installations.

First Doppelmayr 3S gondola lift in Val dʼIsère

In Val dʼIsère, the decision was taken by the operating company STVI (Société des Télépheriques de Val dʼIsère) in 2000 to replace the old Bellevarde 50-passenger reversible, which was built in 1952. The replacement was to be a tricable installation and the contract was awarded to the Doppelmayr company, which had the relevant knowhow following the acquisi-tion of Von Roll's ropeway business. As ten years had passed since the initial development of the system and the carriage, it was considered necessary to upgrade it in line with the state of technology, a job that was entrusted to Bernd Meindl as chief engineer at Doppelmayr. The development work was performed by more than thirty Doppelmayr engineers, and 15,000 man hours were invested. Project planning and the rope calculations were the responsibility of the tricable ropeway pioneer Gottfried Hofmann of Doppelmayr Switzerland.

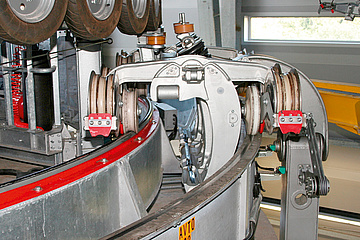

The three grips per carrier employed for the Von Roll tricable system were a floating design. When the carrier passed under a compression sheave train, only the grips pressed against the sheaves without vertical movement in the carrier. For the Doppelmayr 3S system, the three floating grips were replaced by two rigid grips, with flexible compression sheave trains providing smooth passage. The carriages were designed to negotiate curves, which avoided the need for additional wheels to travel through the turnaround. In order to reduce operating noise in the grips, they no longer opened at the top dead center position on the toggle lever mechanism; the grips are only opened at the engaging/disengaging points for gripping/releasing the haul rope and are closed during travel through the station turnaround.

The tricable gondola lift by the name of LʼOlympique has been in operation since 2002 as the only feeder installation to Espace Killy, the biggest ski area in the world. For these tricable gondola lift installations, CWA developed a new cabin for 24 seated and 6 standing passengers.

Safari Express, Kitzbühel

Just two years after the LʼOlympique tricable gondola lift, Doppelmayr built the first 3S gondola lift to take full advantage of all the benefits of the tricable system.

It connects the two ski areas Kitzbühel/Kirchberg (Pengelstein) and Jochberg/Resterhöhe (Talsen) across a deep valley. Before the ropeway was built, there was a bus service linking the ski areas.

The 3,642 m long line of the Safari Express has a vertical difference of only 137 m but it has an extraordinary 2,650 m span between no. 1 tower, the hinged tower at the lower terminal, and the 80 m high no. 2 tower.

For a line length of 3.6 km and an unsupported span of over 2.5 km, the only alternative for the specified transport capacity of 1,600 pph would have been a reversible with two cars for 250 passengers each. As the line has an uphill gradient on the approach to both stations, the system would have to be capable of handling the combined pull of the two cars, which would require a drive with a peak output of 3,500 kW. That is three times higher than for the tricable gondola lift and would have required installation of a new power supply system.

The Safari Express has a number of special features: For example, instead of the middle set of seats, no. 1 cabin has a glass floor for a bird’s eye view from a height of up to 400 m above the ground. The bullwheels have redundant bearings (a prerequisite for integrated recovery, which is now state of technology for 3S gondolas). All the towers and one slack carrier are fitted with anemometers. And the terminal towers nos. 1 and 3 are a hinged design.

Because of the very considerable vertical clearance and the difficulty of accessing the terrain in winter, a system for recovery of stranded cabins along the line was developed: The system comprises four recovery cars, which are lifted onto the rope in the stations with the help of a crane, plus four winches powered by diesel engines for the traction. The carrier grips are released from the haul rope on the line and the carriers towed back to the stations by the recovery cars.

Construction of the first tricable gondola lift in Austria also created the long-awaited link between the Kitzbühel/Kirchberg and Jochberg/Resterhöhe ski areas.

Longest and highest tricable rope span on the Peak 2 Peak Gondola

The fifth member of the 3S family was built to connect the two big North American ski areas Whistler and Blackcomb. It set two ropeway engineering records, for the longest span on a continuously circulating system (3,034 m) and the greatest vertical clearance (415 m), which are still unbeaten today.

The idea of linking the two ski areas was born in 1997 when Hugh Smythe, President of the company that owns Whistler and Blackcomb, and Paul Matthews, President of the Ecosign resort planning company, were in a helicopter during an inspection visit to Zermatt and saw the ropes of the Klein Matterhorn cable car glittering in the sunlight. Hugh Smythe said, “The 2,885 m span between no. 3 tower and the upper terminal is about the same distance as we need to connect our ski areas across the deep gorge of Fitzsimmons Creek.” The main factors in the decision to build what is the most expensive ropeway in North America were operating safety, stability in strong winds and the small environmental footprint.

Implementation of this unique project involved a lot of unusual engineering and organizational challenges, from the constant presence of bears in the area to the installation of the four 4,760 m long ropes weighing 85 t each on a line with such an enormous span.

The 4.5 km line has two towers on either side, with the unsupported span of 3,024 m in-between. The 28-passenger cabins are painted red with the exception of two cabins with a glass panel in the middle of the floor, which are silver.

The Peak 2 Peak Gondola is designed to operate in wind speeds of up to 80 km/h. The cabins are fitted with a radar warning system called OCAS (Obstacle Collision Avoidance System), which serves to warn aircraft of the ropeway with its line slung across the valley.

The Peak 2 Peak was a major boost to the region’s prestige, which was further enhanced by the decision to make it the venue for the 2010 Winter Olympics.

Tricable gondola lift as a local public transport service: the Rittner Bahn

The Leitner company also developed a tricable gondola lift with its own carriage design. It made its debut in 2008 as a replacement installation for the reversible operating between Bozen and Oberbozen (Ritten).

Apart from its low transport capacity resulting from the considerable length of the line (4,566 m), the old reversible was prone to oscillation problems with rope throw-over as a result of the difficult longitudinal profile. When a general overhaul became due after 41 years of public service, the decision was taken to build a new installation on the line of the reversible. With space at a premium in the terminal area, the replacement system was to be a compact tricable gondola lift. When the carriers approach the stations, line speed on the whole haul rope loop is reduced from 7.0 m/s to 3.0 m/s and coupling/uncoupling performed at low speed. That made it possible to reduce the length of the stations by 20 m. There is always one carrier in each of the stations, and it waits there until the approach of the next carrier so that loading and unloading is a relaxed affair with stationary cabins.

For the Bozen-Oberbozen 3S system, the cabin manufacturer Sigma created a new design with a capacity of 35 persons, 70-80% of them seated. At the time, that made them the biggest cabins on a tricable gondola lift. Originally the Ritten tricable gondola lift was operated with eight cabins (rated capacity 550 pph), but another two were added in early 2015 to make it ten (rated capacity 720 pph). When operating at full capacity, the system therefore has 4 + 4 cabins on the line (plus one in each of the stations), but in slack periods the system can also be operated with 3 + 3, 2 + 2 or even 1 + 1 cabins on the line.

The ropeway provides a 17-hour public service daily. Like the funicular serving the Mendel, it is owned by Südtiroler Transportstrukturen AG (STA) and operated by SAD Nahverkehr AG.

First urban 3S gondola lift for Koblenz

The first tricable gondola lift to be built on German soil was an urban transportation system, namely the attractive and eco-friendly visitor ropeway installed for the 2011 Federal Horticultural Show in Koblenz. Since June 2010 it has served as a link between the parks and gar-dens along the River Rhine and the Ehrenbreitstein fortress plateau. With a line length of just under a kilometer and a vertical clearance of up to 40 m over the Rhine, this 3S installation passes over a busy railway line and a main road and provides an impressive view of the Upper Middle Rhine Valley.

When it was built, its rated capacity of 3,800 pphpd put it top of the list for tricable gondola lifts. It was also the first installation to employ the new integrated recovery system. This involves redundant engineering for all functionally relevant system components to ensure that the cabins can be returned to the stations safely whatever fault occurs, a solution that makes it possible to build ropeways where evacuation problems had previously ruled out that option.

The Koblenz cable car across the Rhine cost about EUR 12 million.

Because of claims of adverse effects on the UNESCO Upper Middle Rhine Valley World Heritage Site, the 3S lift was initially only issued with a temporary operating permit up to 2013. Following complicated negotiations, a public demonstration in Koblenz and a petition bearing over 100,000 signatures in support of the continuation of public services, a reassessment was performed. Finally, at a meeting of the World Heritage Committee held in Phnom Penh on June 19, 2013, UNESCO agreed to permit operations to continue until 2026. That means the ropeway, which is very popular with locals and tourists alike, can remain in service until the end of its planned technical life. This tricable gondola lift also has a cabin with a glass panel in the middle of the floor.

The ropeway is operated by Skyglide Event Deutschland GmbH of Lindau (Lake Constance), a one-hundred-percent subsidiary of Doppelmayr, who also make use of the Koblenz 3S gondola as a demonstration installation.

3S gondola lift starring with James Bond

As a replacement for a DLM ropeway (double loop monocable) built in 1988 to serve the Gaislachkogl in Sölden, two new Doppelmayr ropeways were opened in December 2010. They must be considered masterpieces in terms of both design and engineering: The first stage is an 8-seater gondola lift with a rated capacity of 3,600 pph, which was the highest of any gondola lift anywhere in the world until 2016, while the second stage is a tricable gondola.

Apart from the new recovery system, the 3S installation was special for the solutions adopted to solve the problems encountered with the footings in the permafrost zone for the no. 3 tower, which weighs 200 t, and the upper station: The footings are continuously ventilated and also fitted with a hydraulic system that permits the structures to be returned to their original position in the case of any movement in the foundation area.

At the turn of the year 2014/15, Sölden became a film set for “Spectre”, the 24th James Bond film starring Daniel Craig (premiere September 2015). The upper terminal, the gourmet restaurant, which opened in 2013, and the 3S lift itself are to be seen several times in the film. The producer, Barbara Broccoli, was delighted with “the 5-star infrastructure from the valley to 3,000 meters above sea-level”, which she and her team made use of before and during the shooting for the film.

Until 2011, the 3S gondola was operated with nine 30-passenger cabins (for a transport capacity of 1,200 pph). Then two 26-passenger cabins were added, each fitted with two water tanks, one under the seat and the other beneath the floor structure. Before that, water was transported in canisters, which had to be loaded into the cabin manually.

Prodains Express in Avoriaz

For the link between Morzine and Avoriaz, a tricable gondola lift by the name of Les Prodains was built by the Leitner-Poma Group in 2013 to replace an 80-passenger reversible supplied by the Applevage company back in 1963. This was the second tricable gondola lift to be built by Leitner. In addition to skiers and snowboarders, it is also used by tourists traveling with their luggage to and from Avoriaz. The installation thus has a combined winter sport and public transport function. For easy loading and unloading, the cabins come to a standstill in the terminals. The top terminal is located underground to minimize its footprint. This tricable gondola lift also has integrated recovery.

3 x 3S for the Winter Olympics in Sochi

For the 2014 Olympic Winter Games in Sochi, Doppelmayr supplied no fewer than three 3S gondola lifts. The Olympic Village cable car was the first 3S installation to be built in two stages with through-running. It served as a feeder installation to the Olympic Village and the Olympic finish area. It has a maximum transport capacity of 4,500 pphpd, which is currently the highest of any ropeway in the word, although it now shares that title with the Giggijochbahn in Sölden, a Doppelmayr 10-seater gondola ropeway that opened in November 2016. Sochi’s Olympic Village 3S gondola also has dedicated carriers for transporting cars and is capable of handling up to 33 cars an hour.

The third 3S installation in Sochi, the Psekhako, held two world records when it opened in 2014 and one still applies: A line speed of 8.5 m/s makes it the world’s fastest detachable ropeway. The 3S record for line length, namely 5,386 m, on the other hand, has since been beaten – by the Fansipan Legend 3S gondola (6,326 m), which opened in 2016 – and the current record will be broken this year with the opening of the Hòn Thơm 3S gondola in Phú Quốc, Vietnam, which is a staggering 7,900 m long.

Luxury and high tech: the 3S Pardatschgrat, Ischgl

The 3S gondola lift built by Doppelmayr in Ischgl to replace an old 4-seater gondola is a light-house installation for the ski area in terms of both architecture and ropeway engineering. With its combination of luxury and high-tech solutions, it surpasses everything that came before it. In the bottom station built over the Fimbabach stream, the CWA Taris cabins, which made their debut in Ischgl, are parked underground with the help of vertical carrier conveyors for reasons of space. Due to the difficult geology (permafrost) in the area of the upper terminal, the horizontal forces deriving from rope tension are transmitted to a separate foundation block located 150 m behind the station. In the event of any movement in the foundation area of the upper terminal caused by the permafrost, the complete structure can be hydraulically restored to the correct position. An innovative solution in the form of a carriage wheel generator was implemented for the power supply to the cabins, e.g. for the heated seats. Integrated recovery is now state of technology for 3S lifts.

Until the opening of the Fansipan Legend tricable gondola lift, the Pardatschgratbahn held the world record for vertical height (1,257 m) for gondola ropeways.

Penkenbahn – round the bend with a 3S gondola lift

In Mayrhofen, a bicable circulating system built in 1995 was replaced by a Doppelmayr 3S gondola which opened in December 2015. As it has the same line and tower locations as the old installation, the tricable gondola lift also has a horizontal deflection of 6.5° at the first tower. The design and construction of such a tower involved not only extensive calculations and investigations but also the further development of the simulation software used. A test curve was built at the Doppelmayr plant in Wolfurt and three months of material and function tests performed. Modifications were also made to the 3S carriage for optimum negotiation of the curve in the line. A new guide sheave was developed to deal with the significantly higher deflection forces in the curve, and the rope position detector on the deflection tower is also a new design.

In addition to the attractive station architecture, the new Penkenbahn features elegant Taris cabins from CWA in the corporate design of Mayrhofner Bergbahnen.

The other technical highlights of the new 3S gondola include the vertical conveyors for carrier parking, on-board wifi entertainment, automatic battery charging, a fully automatic central lubrication system for the track rope saddles on all the towers, the Easy Boarding system first employed by Serfauser Bergbahnen – and the integrated recovery system, of course.

Fansipan Legend – world record holder in Vietnam

February 2016 saw the opening of a spectacular 3S installation built by Doppelmayr/Garaventa to serve a high-level plateau near the summit of the 3,143 m high Fansipan. As the highest mountain in Vietnam, the Fansipan is a big attraction but one that is very hard to reach. The new ropeway makes it possible for less experienced walkers to visit the “Roof of Indochina” all year round. In just 15 minutes, the single stage of the 6,326 m long 3S gondola lift overcomes a vertical rise of 1,410 m. The Fansipan Legend is currently the longest tricable gondola lift with the greatest vertical rise worldwide. The construction work for the ropeway was equally extraordinary: As only the lower terminal had truck access, the foundations for all the towers and the upper terminal were excavated manually using picks and shovels. Even the tools and equipment had to be carried to the upper terminal over a distance that took several days to walk. Together with the local workforce, the Doppelmayr/Garaventa teams achieved a remarkable feat. The CWA Zeta cabins, which have been finished in various colors, can carry thirty seated passengers. The Fansipan Legend is the second ropeway in the world to have cabins supplied with electricity by a carriage wheel generator. The enormous drive power re-quired for the 3S installation is delivered through a double drive train with two gearboxes and four motors with a total output of 1,630 kW.

In the interest of reliable control of the huge total moving mass, namely up to 500 t, Doppelmayr designed a new braking system plus the software needed for precise calculation of the braking forces required for safe operation in combination with optimum quality of the ride during braking. Doppelmayr also invested a lot of time and knowhow in a professional solution to the design of the station structures in the light of the mass-related dynamics of the installation. The Fansipan Legend is the first ropeway to have the safety section incorporated inside the station building, both at the top and at the bottom – and not after the station as is usually the case.

The Fansipan 3S gondola ropeway went into service shortly before the Chinese New Year, which was only possible thanks to the outstanding collaboration of all concerned in the construction work and the Sun Group.Eisgratbahn, Stubai Glacier

The Stubai Glacier ski area recently opened a high-tech tricable gondola lift built by Leitner, which is now the longest two-stage tricable gondola lift in the Alps and the first with through-running between the stages. It features a number of innovative solutions and in general can be considered a masterpiece of ropeway engineering from South Tyrol.

Matterhorn Glacier Paradise – the world’s highest tricable gondola lift

As a parallel installation to Europe’s highest ropeway, the reversible built in 1979 from Trockener Steg to Klein Matterhorn, Leitner is building the world’s highest tricable gondola (mountain terminal 3,821 m a.s.o.) in the course of three summer construction periods. With double access to this, the only all-year ski area in Switzerland, it will be possible to maintain operations when one of the ropeways is closed for inspections or maintenance. As in the case of the Stubai Glacier, the system will operate with a 1,072 kW DirectDrive supplied by Leitner, which means minimum noise emissions and less wear. A simplified haul rope return configuration and patented spring-loaded haul rope sheaves on the towers also mean less wear on the haul rope. As an additional attraction, the new ropeway – like the Eisgratbahn – will operate with 25 extremely elegant high-tech Symphony cabins in the Pininfarina look supplied by the cabin manufacturer Sigma, which were unveiled at the Leitner stand at Interalpin in 2015.

Next record-breaking 3S gondola lift in Vietnam

It almost looks as if none of the world records set by a tricable gondola lift are likely to remain unbeaten for long. As this brief summary of the history of tricable gondola lifts shows, many of the records set in the past have soon been surpassed by a newer, even more impressive installation. Impressive is certainly the word for Vietnam’s Hòn Thơm – Phú Quốc cable car, which has already been completed and is due to go into service this year. With a line length of 7,900 m, it is the second longest single-stage passenger ropeway ever built.2) The new 3S gondola crosses the sea between the islands of Hòn Thơm and Phú Quốc, with two towers up to 160 m high located on two small islands. Like the 3S Fansipan Legend, the world record-holding reversible across Ha-Long Bay and several other ropeways, the new tricable gondola lift has been built by the Vietnamese Sun Group Corporation in collaboration with the Doppelmayr/Garaventa Group.

1) Gottfried Hofmann is the author of “Ropeway Technology”, a masterpiece of ropeway literature published in 2015 (see ISR 5/2015, pp. 8–11).

2) The world record for the longest single-stage passenger ropeway has been held since 1989 by the Norsjö bicable gondola ropeway in Lapland (Sweden), which has a line length of 13,613 m. Prior to conversion to passenger transportation with 4-seater gondolas, the installation formed the fourth stage of the Linbanan Boliden – Kristineberg material-handling ropeway, which had a total length of 96 km.

![[Translate to English:] (c) Doppelmayr](/fileadmin/_processed_/b/3/csm_85-ATW_Stechelberg-Muerren_Lauterbrunnen_CHE_001_6442c0520d.jpg)